ERA

| Size: | |

|---|---|

| Availability: | |

| Quantity: | |

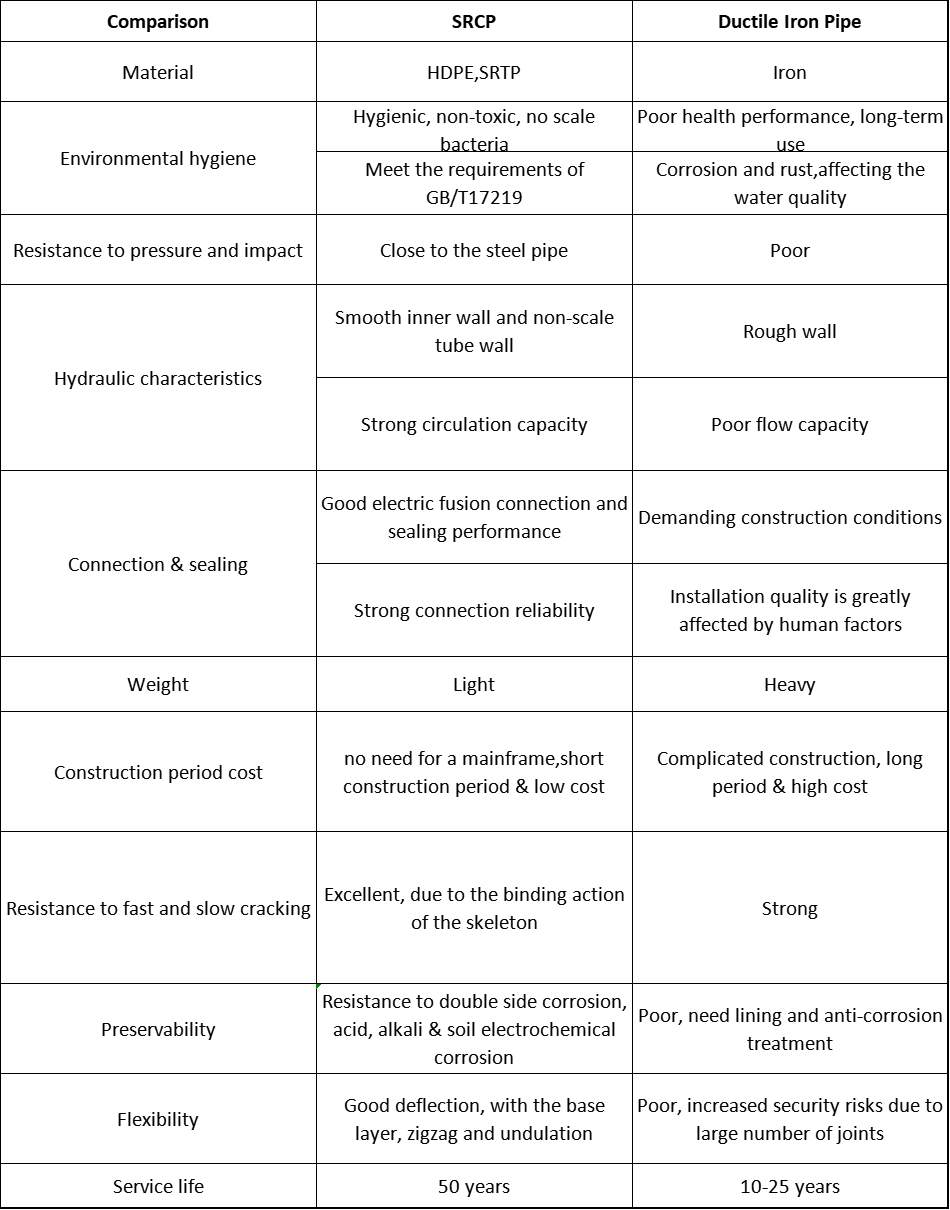

Steel Wire Mesh Reinforced Composite Pipe (SRCP) is a new type of composite structured pressure pipe. It is made of high-strength steel wire and high-density polyethylene (HDPE) plastic. The pipe has a spiral-formed mesh framework as the reinforced core layer, with high-density polyethylene (HDPE) as the inner and outer layers of the pipeline. The steel wire mesh framework is tightly connected to the inner and outer layers of high-density polyethylene (HDPE) with high-performance adhesive resin, forming a solid composite structure for the pipe wall.

By incorporating steel wire reinforcement, the composite pipe significantly improves the pressure resistance compared to solid-wall PE pipes, while retaining the excellent corrosion resistance and scale-free property of PE pipes. The reinforcement layer is enveloped in continuous thermoplastics, ensuring the isolation of the steel wire from the external environment and prolonging its service life, thus ensuring the lasting pressure resistance performance of pipes.

The adhesive resin used in the composite pipe is a high-performance bonding material and belongs to HDPE modified material. It can completely melt and fuse with HDPE under heating. Moreover, its polar bonds have strong adhesive properties with steel. By using the adhesive resin, the problem of no connecting factor between steel and HDPE has been successfully resolved, resulting in a superior composite effect. The steel wire mesh winding process enables the composite pipe a certain flexibility in the axial direction while ensuring a low linear expansion coefficient, and it exhibits strong environmental strain resistance. The pipe is widely used in the water supply field and is considered a new type of practical pipe material.

-Double-sided corrosion protection

-Excellent temperature resistance

-Low thermal expansion coefficient

-Uniform and reliable combination of steel and plastic materials

-Good resistance to creep deformation, high long-term mechanical strength

-Specialized electrofusion joints with diverse varieties, ensuring quick and reliable installation

-Good rigidity, impact resistance, and dimensional stability, while maintaining moderate flexibility

Steel Wire Mesh Reinforced Composite Pipe (SRCP) is a new type of composite structured pressure pipe. It is made of high-strength steel wire and high-density polyethylene (HDPE) plastic. The pipe has a spiral-formed mesh framework as the reinforced core layer, with high-density polyethylene (HDPE) as the inner and outer layers of the pipeline. The steel wire mesh framework is tightly connected to the inner and outer layers of high-density polyethylene (HDPE) with high-performance adhesive resin, forming a solid composite structure for the pipe wall.

By incorporating steel wire reinforcement, the composite pipe significantly improves the pressure resistance compared to solid-wall PE pipes, while retaining the excellent corrosion resistance and scale-free property of PE pipes. The reinforcement layer is enveloped in continuous thermoplastics, ensuring the isolation of the steel wire from the external environment and prolonging its service life, thus ensuring the lasting pressure resistance performance of pipes.

The adhesive resin used in the composite pipe is a high-performance bonding material and belongs to HDPE modified material. It can completely melt and fuse with HDPE under heating. Moreover, its polar bonds have strong adhesive properties with steel. By using the adhesive resin, the problem of no connecting factor between steel and HDPE has been successfully resolved, resulting in a superior composite effect. The steel wire mesh winding process enables the composite pipe a certain flexibility in the axial direction while ensuring a low linear expansion coefficient, and it exhibits strong environmental strain resistance. The pipe is widely used in the water supply field and is considered a new type of practical pipe material.

-Double-sided corrosion protection

-Excellent temperature resistance

-Low thermal expansion coefficient

-Uniform and reliable combination of steel and plastic materials

-Good resistance to creep deformation, high long-term mechanical strength

-Specialized electrofusion joints with diverse varieties, ensuring quick and reliable installation

-Good rigidity, impact resistance, and dimensional stability, while maintaining moderate flexibility

Municipal water supply、Drinking water supply、Fire water supply、Natural gas pipelines

Seawater desalination plants、Coastal power plants、Seawater transport pipelines in harbor cities

Deep well pipes、Filtration pipes、Underground pipelines for irrigation

Oil-contaminated wastewater pipelines、Gas field wastewater pipelines、Oil extraction and transportation pipelines、Pipelines for transporting acids, alkalis, salts, and corrosive gases/liquids/solids

Water supply and drainage systems、Pressurized air pipelines、Slurry transportation pipelines、Gas ventilation pipelines

Municipal water supply、Drinking water supply、Fire water supply、Natural gas pipelines

Seawater desalination plants、Coastal power plants、Seawater transport pipelines in harbor cities

Deep well pipes、Filtration pipes、Underground pipelines for irrigation

Oil-contaminated wastewater pipelines、Gas field wastewater pipelines、Oil extraction and transportation pipelines、Pipelines for transporting acids, alkalis, salts, and corrosive gases/liquids/solids

Water supply and drainage systems、Pressurized air pipelines、Slurry transportation pipelines、Gas ventilation pipelines