Views: 0 Author: Site Editor Publish Time: 2023-06-20 Origin: Site

A plastic valve is a valve made of plastic material that is used primarily for fluid control. They are common in many industrial applications, such as the chemical, water treatment, food and medical industries. Plastic valves are resistant to corrosion, high pressure and high temperature, while also providing effective sealing performance. In addition, they can provide a more cost-effective solution, as plastic materials are relatively cheaper and less expensive to repair. When choosing plastic valves, factors such as fluid properties, temperature, pressure and flow rate need to be considered. In addition, valve design and size also need to take into account the requirements of the application.

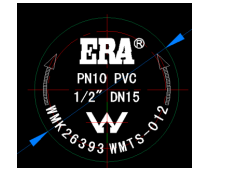

2.1 ERA is the most complete variety of plastic valves and the most

cost-effective manufacturer within the world. Provide one-stop shopping experience for world buyers, save procurement costs and bring convenience to procurement.

2.2 ERA can provide the same type of product with different price positions and different market demands. For example, the single and double union ball valve have the most classic KEY HANDLE TYPE of USU01,and the king of cost performance type USU05 of the same design by TECHNO. ERA dealers can not only capture users who pursue high quality, but also win users who pursue high cost performance.

2.3 ERA invest $2 million USD every year in developing new products to meet the new needs of the market. ERA is currently China's largest exporter of plastic valves, with an annual ball valve production capacity of 55 million pieces. In 2022, the number of ball valves produced has reached 36 million pieces, and the products are exported to 112 countries around the world.

2.4 ERA sold 28 million pieces of ball valves in 2022, with an average of nearly 77,000 ball valves sold every day. Behind this excellent figure are 142 special injection molding machines for ball valves and 8 automatic valve installation equipment. And two automatic pressure test lines, 24 hours uninterrupted production of huge capacity support.

2.5 PVC independent formula, has passed NSF certification; has its own professional accessories factory for ERA sealing accessories. Continuous optimization of raw material formula, product structure to reduce costs, automatic installation pressure test to reduce labor costs, volume of sales to reduce management costs, for ERA to continuously create better prices, but also to provide strong support for quality improvement.

1. Q: Types of ERA PVC Valves?

ERA VALVE TYPES | ||

TYPES | FUNCTIONS | PRODUCTS |

STOP VALVE | Used to cut off or connect the medium in the pipeline | Such as: COMPACT ball valve, double union ball valve, single double union ball valve, globe valve, gate valve, butterfly valve, etc |

CHECK VALVE | Used to prevent backflow of media in pipes | Such as: foot valve, swing type check valve, single spring type check valve, double check valve, drainage check valve, etc |

Distribution valve | Used to change the flow direction of media, and to distribute, separate and mix media | Such as Three-Way Valve |

VALVE Accessories | Used for the connection between the pipe end and the valve end, the connection is more convenient and flexible | Such as: flange, expansion coupling, coupling,Unions etc |

2. Q: Can the PVC VALVES be OK to use in hot water?

A: No. PVC ball valves can not be used for hot water. Especially they are not suitable for use in applications where the water is pressurized, as they are not designed to withstand high pressures.

3. Q: Is it safe for the PVC valve to be used in portable water?

A: Drinking water can be transported safely using PVC pipes. This is a result of their high level of inertness and corrosion resistance. Therefore, PVC pipes and valves are devoid of biofilm contamination, which could serve as a bacterial nidus. PVC pipes contribute to the provision of clean water, which is good for everyone’s health.

4. Q: How to use a PVC valve to join into a pipe or fittings?

A:Installing a PVC ball valve into a PVC pipe is a simple process that anyone can do with the right tools and instructions. Here is what you need to know in order to join a PVC ball valve into a PVC pipe:

First, gather the necessary supplies. You will need a PVC ball valve, a length of PVC pipe, PVC primer, PVC cement, and a hacksaw. Make sure that the ball valve and the pipe are of the same diameter.

Next, use the hacksaw to cut the PVC pipe to the desired length. Once the pipe is cut, clean up any rough edges with sandpaper.

Now its time to apply the primer and cement to both the inside of the pipe and outside of the valve. Join the two pieces together and hold for 30 seconds while the cement sets.

5. Q:What’s ERA VALVE sales distribution and market

situation?

The United States is the market with the largest sales volume. It has high requirements for product price and quality, especially for quality stability. ERA has monopolized all the plastic ball valves of HOMEDEPOT, LOWES and MERNARDS, the top three building materials suppliers in the United States. Their requirements for cost performance are much more stringent than wholesale channels. To monopolize their supply channels, it is ERA's strength and ability.

3.1 United States NSF certification

NSF is an authority in the field of public health and safety, specializing in setiting standards, product testing and certification services in the field of public health, safety and environmental protection. As a neutral third party, NSF certification of American and international standards has been approved and certified by 13 national or industry authority organizations, including the American National Standards Institute (ANSI), the United States.

3.2 United States UPC certification

U. P. Code stands for "Uniform Plumbing Code" and is part of the additional certification that is done in conjunction with the NSF14 Performance assessment. UPC and cUPC certification is the passport to enter the United States and Canada. The U.P. Code mark indicates that your product has been evaluated in accordance with applicable standards and requirements in the Plumbing Code .

3.3 Watermark Certification in Australia

The Watermark is a certification mark from Standards Australia Limited. Certified products include faucets, all kinds of water valves, water pipes, water tank accessories, shower, bathtub, pipe joints and other water supply, sewage products.

The WATERMARK is a product quality certification provided by an independent certification body to ensure that the product complies with Australian sanitary regulations and product standards. This certification is mandatory for all sanitary products installed in Australia according to the Australian Sanitary Regulations.

Introduction:

Polyvinyl chloride (PVC) valves have emerged as indispensable components across a multitude of industries, offering a versatile solution for fluid control and management. The inherent properties of PVC, a robust thermoplastic material, make PVC valves a preferred choice in applications ranging from water supply and irrigation to chemical processing and HVAC systems. In this comprehensive exploration, we will delve into the diverse applications of PVC valves, highlighting their adaptability, durability, and cost-effectiveness across different sectors.

1. Water Supply and Distribution:

One of the fundamental applications of PVC valves lies in water supply and distribution systems. Municipalities and water utilities worldwide rely on PVC valves to regulate water flow, control pressure, and direct water within extensive networks. PVC valves, known for their corrosion-resistant nature, ensure a consistent and reliable water supply, making them a staple in the infrastructure supporting communities.

PVC valves excel in managing the challenges posed by varying water conditions, from potable water distribution to wastewater systems. The material's resistance to corrosion and degradation ensures the longevity of these valves, contributing to the overall efficiency and sustainability of water supply networks.

2. Irrigation Systems:

In the agricultural sector, PVC valves are instrumental in the development of efficient irrigation systems. Farmers and landscapers leverage PVC valves to control the flow of water to different sections of fields and gardens. The durability of PVC makes it well-suited for outdoor applications, withstanding exposure to sunlight, soil moisture, and fluctuating weather conditions.

PVC valves in irrigation systems offer precise control over water distribution, enabling optimal soil moisture levels for crops. Their reliability, ease of installation, and low maintenance requirements make PVC valves a practical choice for agricultural practices seeking sustainable and efficient water management solutions.

3. Chemical Processing Industries:

The chemical processing industry relies heavily on materials that can withstand the challenges posed by corrosive substances. PVC valves prove invaluable in this context due to their exceptional chemical resistance. These valves play a critical role in the transportation, regulation, and containment of acids, bases, and other corrosive materials within chemical plants and processing facilities.

Chemical engineers and plant operators appreciate the reliability of PVC valves in maintaining the integrity of fluid control systems. The resistance of PVC to a wide range of chemicals enhances safety and operational efficiency, making PVC valves a cornerstone in chemical processing applications.

4. HVAC Systems:

Heating, ventilation, and air conditioning (HVAC) systems benefit significantly from the application of PVC valves. These valves contribute to the regulation of fluid flow in HVAC systems, ensuring efficient heating and cooling processes. The lightweight nature of PVC valves makes them easy to handle and install, reducing the overall weight and complexity of HVAC systems.

PVC valves are particularly advantageous in HVAC applications where exposure to moisture and temperature variations is common. Their resistance to corrosion and rust makes them a reliable choice for both residential and commercial HVAC systems. Additionally, the affordability of PVC valves adds a cost-effective element to HVAC projects, making them accessible for various applications.

5. Pool and Spa Systems:

The recreational sector also embraces PVC valves in pool and spa systems. PVC valves are crucial components in the plumbing infrastructure of swimming pools and spa facilities, where they regulate water flow, control backflow, and manage the distribution of chemicals for water treatment.

The resistance of PVC to the chemicals commonly used in pool maintenance, such as chlorine, ensures the longevity and reliability of valves in these systems. PVC valves contribute to maintaining water quality and circulation, playing a pivotal role in the overall functionality and safety of pool and spa installations.

6. Manufacturing and Industrial Processes:

PVC valves find applications in diverse manufacturing and industrial processes where fluid control is essential. Whether in the management of cooling water, chemical handling, or material conveyance, PVC valves offer a reliable and cost-effective solution. Industries such as textiles, food and beverage, and automotive manufacturing benefit from the versatility and durability of PVC valves.

Manufacturing processes often involve the use of diverse fluids, some of which may be corrosive or abrasive. PVC valves, with their chemical resistance and robust construction, provide a dependable means of controlling the flow of these fluids, contributing to the efficiency and safety of industrial operations.

7. Waste and Sewage Systems:

In waste management and sewage systems, PVC valves play a critical role in controlling the flow and direction of effluent. The corrosion-resistant properties of PVC make these valves ideal for applications in sewage treatment plants, septic systems, and wastewater management facilities.

PVC valves contribute to the prevention of leaks and contamination in waste and sewage systems, ensuring the safe and effective disposal of wastewater. Their durability in the face of harsh environmental conditions and corrosive substances makes PVC valves a reliable choice for the infrastructure that supports sanitation and waste management.

8. Marine and Aquaculture Applications:

In marine environments and aquaculture operations, where exposure to saltwater and harsh conditions is inevitable, PVC valves demonstrate their resilience. These valves find application in boat plumbing, seawater desalination systems, and aquaculture setups, where they regulate water flow and contribute to the overall efficiency of marine operations.

The resistance of PVC to saltwater corrosion and its ability to withstand the challenges of marine environments make PVC valves a preferred choice for various marine applications. Their low maintenance requirements and durability contribute to the reliability of fluid control systems in marine and aquaculture settings.

Conclusion:

In conclusion, the extensive applications of PVC valves underscore their versatility and reliability across diverse industries. From water supply and irrigation to chemical processing, HVAC systems, and beyond, PVC valves continue to play a crucial role in fluid control and management. The unique combination of chemical resistance, durability, and cost-effectiveness positions PVC valves as a cornerstone in the development of sustainable and efficient systems across the spectrum of modern industries. As technology and engineering advancements continue, the role of PVC valves is likely to expand, further solidifying their status as indispensable components in fluid control applications.

4. What’s the application filed of ERA Valves?

ERA have exported our PVC valves to 121 countries and regions in the world. Our products are widely used in civil buildings, agricultural irrigation system, swimming pool, water treatment equipment Industrial piping lines , etc.,

4.1 Civil buildings

4.2 agricultural irrigation system

4.3 Swimming pool

4.5 Water treatment equipment

1. Characteristics of PVC ball valve

PVC ball valve is a valve made of PVC material. There is a spherical channel inside the ball. The medium is cut off or connected by rotating the ball. PVC ball valve has the following characteristics:

1.1 Lightweight: PVC material has low density and light weight, which is convenient for installation and maintenance.

1.2 Corrosion resistance: PVC material has good corrosion resistance and can be used for a long time in corrosive media such as acid and alkali.

1.3 Wear resistance: The surface of the PVC ball valve is smooth and the friction coefficient is small. It can maintain a long service life in occasions of frequent switching.

4. Good sealing: The sealing ring made of PTFE and other materials between the PVC ball valve ball and the valve seat can ensure good sealing performance.

2. Application fields of PVC ball valve

PVC ball valve is widely used in the following fields due to its lightness, corrosion resistance, wear resistance and good sealing performance:

2.1 Construction: PVC ball valve can be used for fluid control in building water supply and drainage, air conditioning, HVAC and other systems.

2.2 Chemical industry: PVC ball valves can be used for fluid control in chemical production, such as the transportation and regulation of acid, alkali, salt and other media.

2.3 Environmental protection: PVC ball valves can be used for fluid control in environmental protection equipment, such as wastewater treatment, gas purification, etc.

2.4 Water treatment: PVC ball valves can be used for fluid control in fields such as tap water and sewage treatment.

3. Precautions for the use of PVC ball valves

3.1 Temperature and pressure limits: Due to the material limitations of PVC ball valves, their operating temperature and pressure ranges are relatively low, and they are generally suitable for low-pressure and low-temperature fluid control.

3.2 Avoid improper operations such as excessive twisting and stretching: During installation and use, it is necessary to avoid improper operations such as excessive twisting and stretching to avoid affecting its service life and sealing performance.

3.3 Choose the right specifications: When purchasing PVC ball valves, it is necessary to choose the right specifications according to the actual use occasions to ensure its normal use.

In short, PVC ball valves are a type of valve with excellent performance and wide use, suitable for a variety of fluid control occasions. During use, it is necessary to pay attention to its material limitations and use conditions to ensure its normal use and extend its service life.

Function of ball valve

The ball valve is defined in the standard GB/T21465-2008 "Valve Terminology" as: a valve in which the opening and closing part (ball) is driven by the valve stem and rotates around the axis of the valve stem. It is mainly used to cut off or connect the medium in the pipeline, and can also be used for fluid regulation and control. Among them, the hard-sealed V-type ball valve has a strong shear force between the V-type ball core and the metal valve seat of the hard alloy surfacing, which is particularly suitable for media containing fibers, tiny solid particles, etc. The multi-way ball valve can not only flexibly control the confluence, diversion, and flow direction switching of the medium on the pipeline, but also close any channel and connect the other two channels. This type of valve should generally be installed horizontally in the pipeline. Ball valve classification: pneumatic ball valve, electric ball valve, manual ball valve.

Technical parameters

Applicable fluids: water, air, oil, corrosive chemical liquids

For example: pure water and raw drinking water pipeline systems, drainage and sewage pipeline systems, salt water and seawater pipeline systems,

acids, alkalis and chemical solution systems and other industries.

Valve body material: PVC

Sealing material: EPDM/PTFE

Transmission mode: 90º rotary electric drive

Actuator material: cast aluminum alloy/plastic shell

Protection device: overheat protection

Action time: 4-30 seconds

Nominal pressure: 1.0Mpa

Nominal diameter: DN15-200

Protection level: IP65

Fluid temperature: -15℃-60℃ (no freezing)

Ambient temperature: -25℃-55℃

Power consumption: 8VA-30VA

Installation method: installation at any angle (horizontal or tilted installation is best to extend life)

Power supply voltage: standard AC220V, optional DC24V, AC110V

Voltage tolerance: ±10%, DC tolerance ±1%

Connection method: internal thread, bonding, flange

Connection diameter: 1/2”-4”

PVC ball valve is mainly used to cut off or connect the medium in the pipeline, and can also be used for fluid regulation and control. Compared with other valves, it has the following advantages. 1. Small fluid resistance. The ball valve has the smallest fluid resistance among all valve types. Even the reduced diameter ball valve has a very small fluid resistance. The UPVC ball valve is a new material ball valve product developed according to the needs of various corrosive pipeline fluids. Product advantages: light weight and strong corrosion resistance of the valve body, compact and beautiful appearance, light weight and easy installation of the body, strong corrosion resistance, wide application range, hygienic and non-toxic material, wear resistance, easy disassembly, and simple and easy maintenance.

In addition to PVC plastic materials, plastic ball valves also have PPR, PVDF, PPH, CPVC, etc. PVC ball valves have excellent corrosion resistance. The sealing ring adopts F4. Excellent corrosion resistance and extended service life. Flexible rotation and easy to use. As an integral ball valve, the PVC ball valve has fewer leakage points and high strength, and the connection type ball valve is easy to install and disassemble. Installation and use of the ball valve: When the flanges at both ends are connected to the pipeline, the bolts should be tightened evenly to prevent leakage caused by flange deformation. Turn the handle clockwise to close, and vice versa to open. It can only be used for flow interruption and flow, and flow adjustment is not recommended. Liquids containing hard particles can easily scratch the ball surface.